Story by Helen Hill for MGHPCC

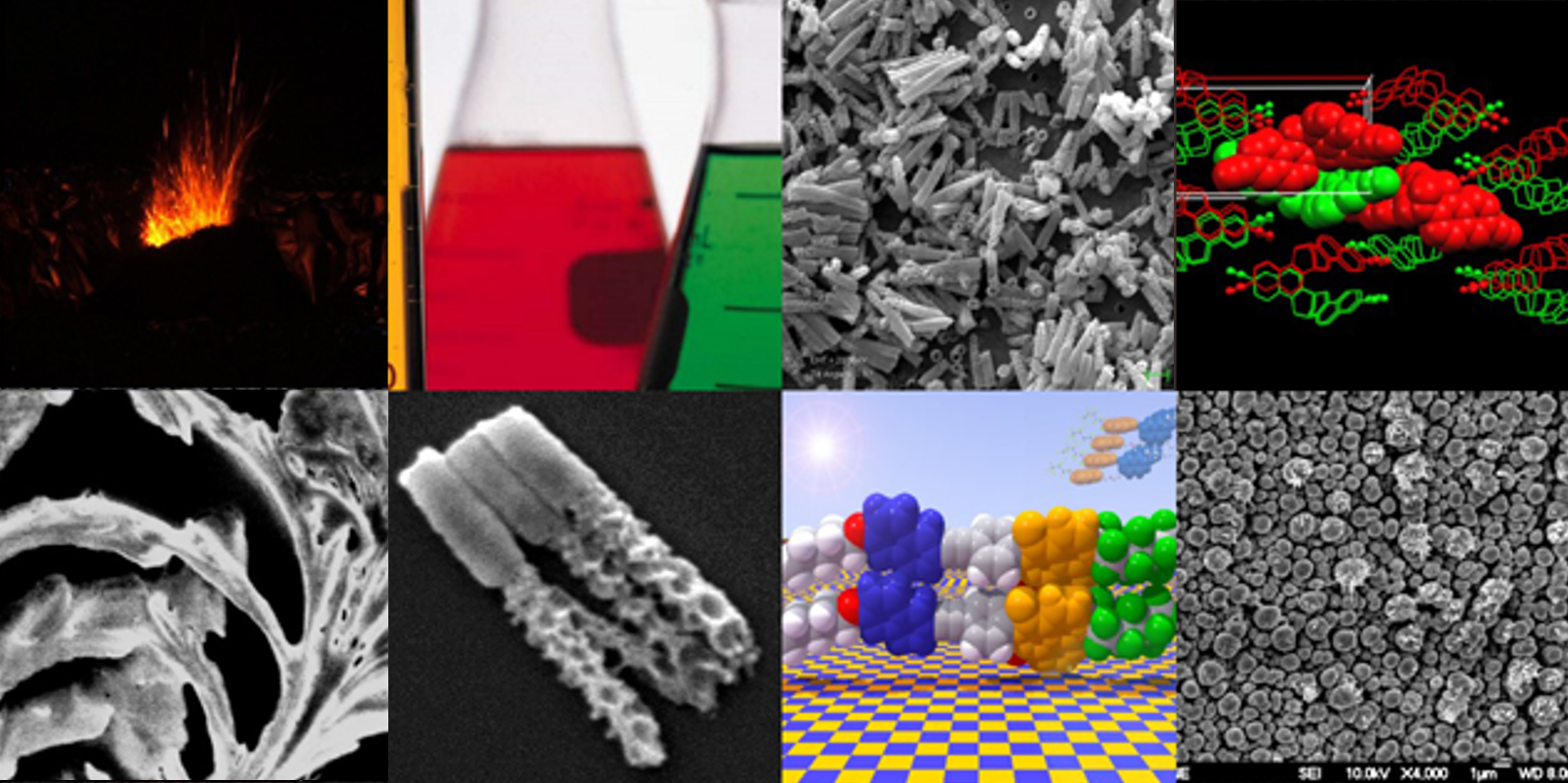

UMass Amherst chemist Dr. Dhandapani Venkataraman and his group are developing a new concept that assembles nanoparticle Lego-like building blocks (<100 nm in size) into new and innovative materials like solar cells, batteries, paints, sensors, and smart and temperature responsive materials. Along with the physical tools of synthetic chemistry the computing facilities provided by the MGHPCC are key in helping Venkataraman evaluate these new materials and their properties.

Nanoparticles are a hot topic in materials science with enormous potential for innovation. They bridge between the macroscopic world of bulk materials and the microscopic world of atomic or molecular structures. Bulk materials generally have constant physical properties regardless of their size but at the nano-scale, where the percentage of atoms in the surface of each particle becomes significant, interesting and sometimes unexpected properties arise. The Dhandapani Venkataraman (DV) Group’s approach is unique because it allows different components to be individually optimized for their behaviors on the nanoparticle scale, and then assembled into an overall macroscopic (composite) structure according to what properties are desired. Moreover, the materials the team is working on are processed from water, ensuring an environmentally friendly process.

"This has been an elusive but much sought after strategy in materials design. Such an ab-initio approach enables, in a systematic and efficient manner, a spectrum of functionalities and a toolbox promising a range of new technologies. It also establishes a new paradigm for hierarchical molecular self-assembly and materials design in which the chemist not only assembles the molecules but then goes on to assemble the molecular assemblies!" explained Venkataraman.

Graduate Students Larry Renna (left) and Christie Cutting (right) looking at nanoparticle dispersions. Photo Credit Lisa Korpiewski

In a recently published collaboration with UMass Amherst Chemical Engineering colleagues, lead author DV Group graduate student Lawrence Renna et al. reports on research exploring how changing the ratio of the two nanoparticles in something called a semiconducting binary polymer nanoparticle glass can be used to tune electron flow for use in photovoltaic devices (solar cells.)

In the glass we are used to (i.e. windows), the arrangement of the silicon and oxygen atoms is disordered but the interaction between them is nonetheless strong making the glass mechanically robust. If instead of silicon and oxygen atoms two types of nanoparticles are used then the material is termed a binary nanoparticle glass. Glasses are particularly attractive for materials because they are diverse, reproducible, and easily formed.

The binary polymer nanoparticle glass of Venkataraman's study results from the self-assembly of two (binary) nanoparticles made of polymers; the spheres made of polymer self-assembling into a glass.

"A nice way to picture this is to imagine putting two different kinds of colored balls coated with glue in a container and shaking it; when they settle, what you have is essentially a binary particle glass." explained Venkataraman. Because the two different materials are in separate nanoparticles it makes it easy to mix them together in lots of different ways in any desired ratio. "It is like playing with Legos, where the nanoparticles are the Lego building blocks."

The team found that by varying the relative percentages of equal-sized nanoparticle constituents of the binary assembly they could tune how efficiently electrons could percolate through the glass.

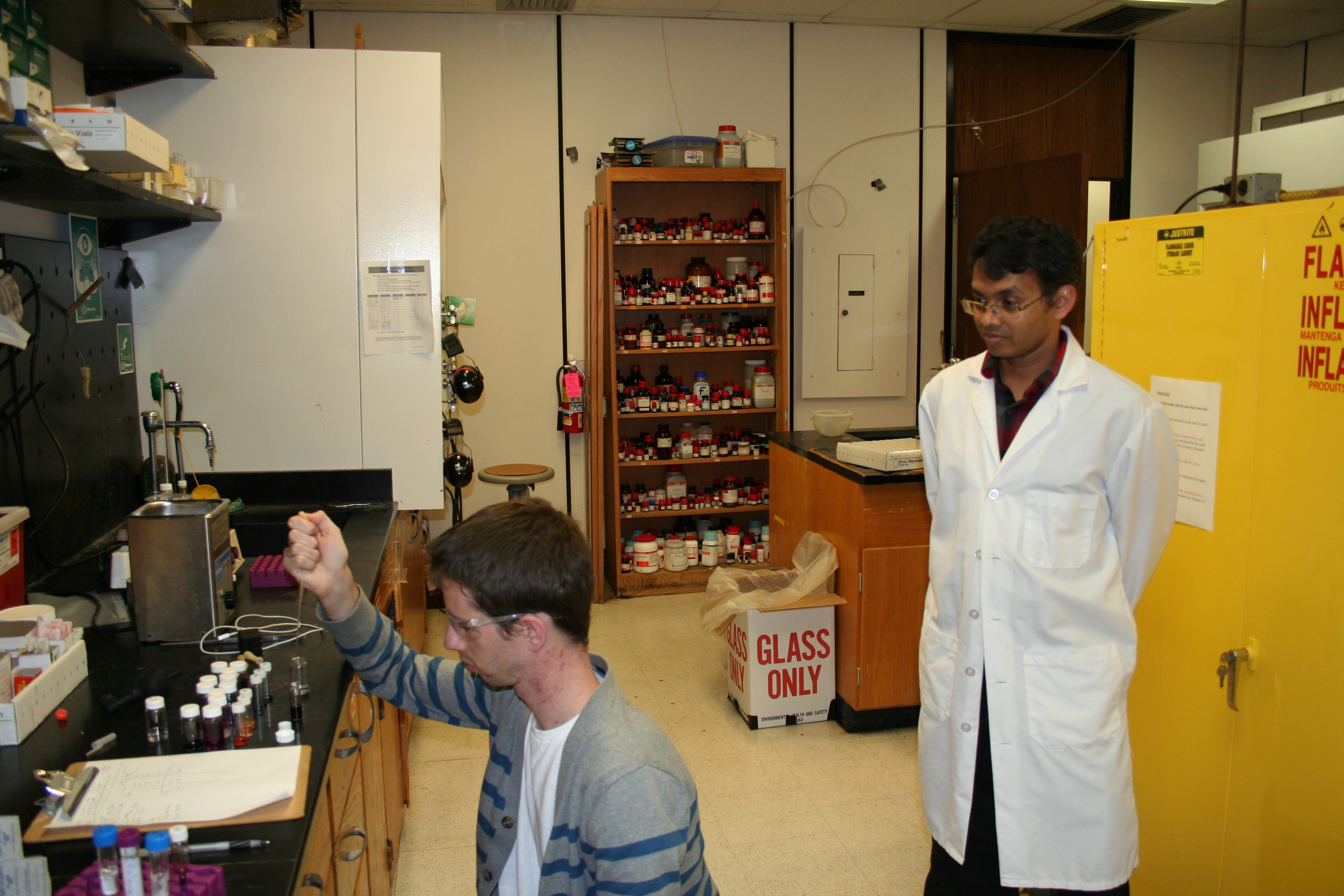

Graduate Student Tim Gehen and Postdoctoral Associate Dr. Monojit Bag fabrication solar cells from nanoparticle dispersions - Image courtesy: The DV Group

The Venkataraman group is currently using these assemblies to fabricate efficient organic solar cells and ion-transporting materials.

About the Researchers:

Watch this short video to learn more about work in the DV Group:

DV's Research - Video courtesy: DV Group.

Publication:

Lawrence A. Renna, Monojit Bag, Timothy S. Gehan, Xu Han, Paul M. Lahti, Dimitrios Maroudas, and D. Venkataraman (2016), Tunable Percolation in Semiconducting Binary Polymer Nanoparticle Glasses, J. Phys. Chem. B, Article ASAP,

doi: 10.1021/acs.jpcb.5b11716

Related Links:

The Venkataraman Group Department of Chemistry, University of Massachusetts, Amherst